Equipment corrodes in harsh environments such as along the coast or in hot spring areas.

Rust Preventive Powder Coating protects your equipment from corrosion!

Are you having trouble with metal equipment corroding in harsh environments such as salt-damaged areas near the coast, humid environments such as inside tunnels and dams, or environments exposed to sulfur gas such as hot spring areas or near volcanoes?

Zinc plating alone is not a sufficient anti-corrosion measure. In addition to reducing costs by extending the lifespan of equipment, measures are required that also take into account safety for the human body and the environment.

NTT Group's anti-corrosion powder paint Rust Preventive Powder Coating, which has a proven track record as a countermeasure against metal corrosion, will solve your problems.

- Demonstrates excellent rust prevention ability even under severe corrosive conditions such as salt damage, volcanic gas, and hot spring gas.

- Can be applied directly to galvanized surfaces (no primer required)

- Highly adheres to the substrate and strongly protects the substrate for over 35 years *

- Uses resin that is safe for the human body and does not contain VOC (volatile organic compounds), so it is friendly to people and the environment.

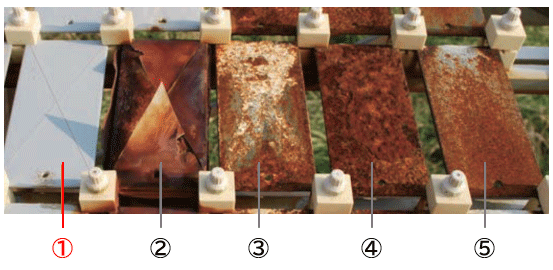

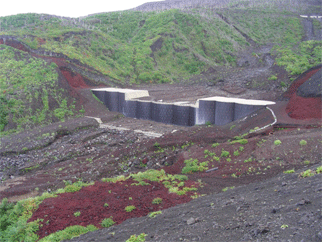

Demonstrates anti-rust power even in environments near volcanoes! Outdoor exposure test on Miyakejima (after 11 years)

The photo shows an outdoor exposure test on Miyakejima (after 11 years).

Galvanized steel sheets coated with Rust Preventive Powder Coating show no rust, even in the cross-cut areas. The "polyethylene paint," "thermosetting polyester paint," "galvanized steel sheet," and "Zn-Al-Mg-plated steel sheet" that were exposed at the same time were covered in red rust.

The testing site is close to the coast and is in a heavily salt-damaged area where, depending on the direction of the wind, it can be directly hit by sea spray. Furthermore, we experienced exposure to volcanic gas due to the eruption of Mt. Oyama in 2000. It can be seen that Rust Preventive Powder Coating exhibits extremely high rust prevention performance not only against salt damage but also against volcanic gas.

Various test results

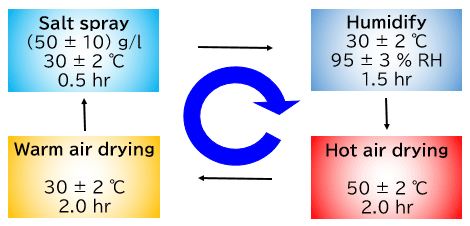

Combined cycle corrosion test

These are the results of a combined cycle corrosion test in accordance with JIS K 5600-7-9:2006 (D method).

- Test period: 1,320 cycles (330 days) of 6 hours per cycle (equivalent to over 10 years in outdoor environment)

- Test piece: A test piece made of a hot-dip galvanized steel plate (150 x 70 x 3.2 mm equivalent to HDZT77) coated with Rust Preventive Powder Coating to a thickness of approximately 300 μm (with cross-cuts)

Weather resistance test

- Test equipment: Sunshine weather meter

- Test time: 10,000 hours

- Test conditions: Black panel temperature: 63±3℃, fresh water spray: Sprayed for 18 minutes during 120 minutes of UV irradiation

Appearance of each test piece after testing

Rust Preventive Powder Coating specimen shows no discoloration or fading.

salt spray test

- Test equipment: salt spray test machine

- Exam time: 2,000 hours

- Test pieces:

①Test piece of hot-dip galvanized steel plate (back side is blasted) coated with Rust Preventive Powder Coating to a thickness of approximately 300μm

(There is a cross cut part on the surface)

②Hot-dip galvanized steel plate (back side is blasted)

① After salt spray test Rust Preventive Powder Coating Appearance of test piece

Although some white rust can be seen on the cross cut part,

No other abnormalities were observed.

② Appearance of hot-dip galvanized steel sheet after salt spray test

Blisters due to red rust can be seen on both sides.

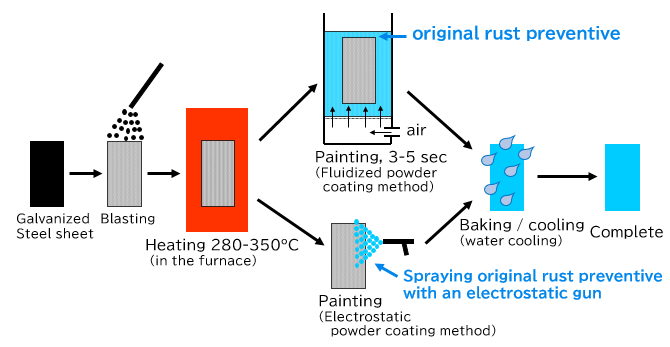

Rust Preventive Powder Coating painting process

Since on-site painting is impossible, factory painting is mandatory.

In the factory, you need a furnace that can heat the object above 300 ℃ and water cooling equipment. If you do not have them, please look for a Powder coating company which has the equipment.

The object to be painted does not necessarily have to be galvanized steel. Please contact us for available materials.

Main performance

| item | performance etc. | Test method etc. | ||

|---|---|---|---|---|

| Initial coating performance | Film thickness | 250~350μm | ー | |

| smoothness | 〇 | Visual observation | ||

| Glossiness | > 90% | JIS K 5400 60° specular gloss | ||

| Hardness | H~F | pencil hardness method | ||

| impact resistance | > 30kg・cm | JIS K 5400 | ||

| Adhesion | >7MPa | Adhesion test method | ||

| Environmental testing | acid resistance | No cracking or peeling abnormalities | Soaked in 10% HCl aqueous solution for 30 days | |

| Alkali resistance | No cracking or peeling abnormalities | Soaked in 10% NaOH aqueous solution for 30 days | ||

| salt fog resistance | No abnormalities such as cracking, peeling, rusting, etc. | JIS K 5400 2000 hours | ||

| accelerated weather resistance | Color difference | No abnormalities such as cracking, peeling, rusting, etc. | JIS K 5400 2000 hours 50% gloss retention rate 500 hours |

|

| Glossiness | ||||

| Outdoor exposure | Color difference | No abnormalities such as cracking, peeling, rusting, etc. | 1 year exposure 50% gloss retention rate 1 year |

|

| Glossiness | ||||

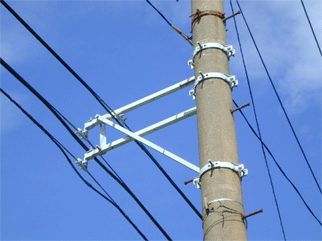

Application example

*The color of the anti-slip processing example is the color of the anti-slip material.

Examples with anti-slip processing are provided by Nakamura Densetsu Co., Ltd.

*Opens in a new window

catalog

| High durability anticorrosive powder coating Rust Preventive Powder Coating ® 5000 Brochure | 650KB | download |

|---|

inquiry

frequently asked Questions

Frequently asked questions regarding powder coating Rust Preventive Powder Coating are introduced as FAQ. Please use it as a reference for product selection.Request for materials / inquiries

Please feel free to contact us using the form for a purchase estimate and details.

close up

close up