Adhesive fixation of the Si waveguide chip and fiber eliminates the need for a high-precision stage during chip characterization, making handling easier.

It can also be combined with a base plate that fixes the chip or a PCB board.

In addition to experimental samples, please use it to create samples for display and storage.

It can also be combined with a base plate that fixes the chip or a PCB board.

In addition to experimental samples, please use it to create samples for display and storage.

Main service contents

Fiber array connection

Adhesive fixation of the chip and fiber eliminates the need for equipment such as a high-precision stage when evaluating chip characteristics, improving the reproducibility of optical characteristics.

Optical evaluation of chips before bonding

Evaluate chip optical loss and spectrum. By performing preliminary evaluation of the chip, it is possible to select a good port and connect it to the fiber.

Combination with PCB board

By connecting the electrode pattern of the chip and the PCB board for development with wire bonding, it becomes easy to evaluate the electrical characteristics.

Features of services for Si waveguides

| Connection method | edge connection only | |

|---|---|---|

facing

|

90° connection

|

|

| Fiber type | single mode fiber, PANDA fiber, Small diameter fiber (MFD* approx. 4 μm), Small diameter PANDA fiber (MFD* approx. 4 μm) |

|

| Chip size | Width: 5mm~, Length: 5mm~ | |

| fiber array pitch | 127μm~ (standard 250μm) | |

| alignment wavelength | 1.55 µm | |

*For connections other than the above, please contact us.

Si waveguide connection example

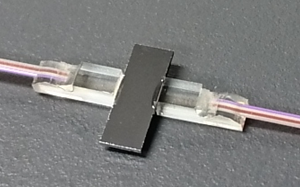

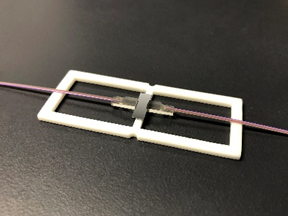

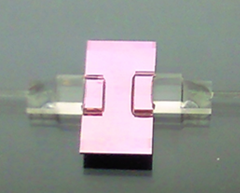

Example of mounting on a fixed frame

A fiber array is attached to both ends of the Si waveguide chip, and attached to a fixed frame to avoid stress on the connection.

It is easy to handle and convenient for evaluation of various chips (electricity, temperature, wavelength characteristics) and storage.

It is easy to handle and convenient for evaluation of various chips (electricity, temperature, wavelength characteristics) and storage.

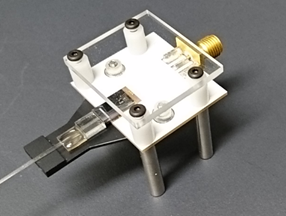

PCB board mounting example

Mounting a Si waveguide on a printed circuit board facilitates the evaluation of electrical characteristics.

We also accept wire bonding processing between PCB substrates and Si waveguide chips.

We also accept wire bonding processing between PCB substrates and Si waveguide chips.

Standard implementation example

| item | content |

|---|---|

| chips | Paid by customer Or you can make it yourself (Silicon waveguide) |

| fiber array | Paid by customer Or you can quote separately |

| End face | Glass application, polishing (perpendicular) |

| Alignment | Align and connect with 2 ports that allow light to pass through |

Fiber array connection example

Small diameter fiber 250μm 4 cores (perpendicular to end surface)

Small diameter fiber 250μm 4 cores (perpendicular to end surface)

close up

close up