We, NTT ADVANCED TECHNOLOGY (NTT-AT), have the material analysis know-how cultivated over many years at NTT laboratories. specializes in the analysis of

We support your research and development with a wide range of service lineups according to your purpose.

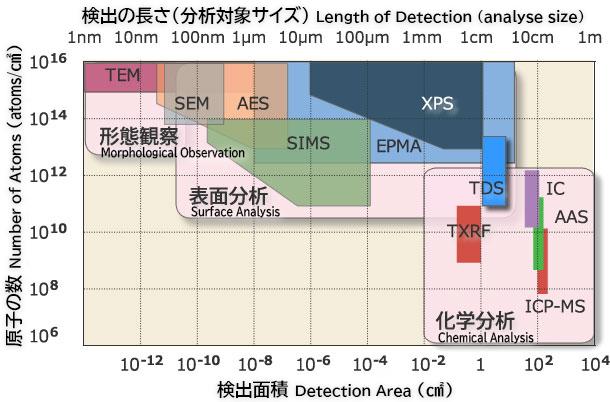

Detection sensitivity and size of analysis method (image)

If you hover the mouse over the name of each analysis method in the figure below, the target size of that analysis will be displayed. Click to go to the details page for each analysis.

* It may not work properly on smartphones and tablets.

Morphological observation

Device, material morphology/structure, composition evaluation

Search by analysis method

| Analysis method | Information obtained | Application example | Surface resolution |

|---|---|---|---|

|

TEMs transmission electron microscope |

Cross-sectional structure | Cross-sectional observation of semiconductor devices, FFT | 0.2nm |

| FIB-SEM | Information such as internal voids and defects | Defect analysis of porous ceramics | |

|

SEM scanning electron microscope |

Observation of surface shape | Detailed shape observation of defective parts | 2nm |

|

AFM atomic force microscope |

Observation of surface microscopic unevenness | Silicon micro-roughness measurement | several nanometers |

surface analysis

Any kind of analysis requires "know-how" including measurement conditions and pretreatment. At our company, we propose the optimal analysis method according to various conditions such as the customer's purpose of analysis, sample condition, resolution and detection sensitivity, etc., and our strength is to perform analysis that reflects the original sample information.

Search by analysis method

| Analysis method | Information obtained | Application example | analysis element and Detection limit concentration |

depth resolution and Surface resolution |

|---|---|---|---|---|

|

SIMS Secondary ion mass spectrometry |

I want to obtain the concentration of impurities with high sensitivity. | Dopant depth distribution | H~U ppb to ppm |

A few to several tens of nm 1 to several tens of μm |

|

XPS X-ray photoelectron spectroscopy |

Surface composition and chemical state | Surface oxidation state, surface contamination | Li to U 0.1-1% |

>2nm >30μm |

|

AES Auger electron spectroscopy |

Structure depth information Elemental analysis of minute parts |

Structure of thin film, qualitative analysis of contaminants | Li to U 0.1-1% |

>2nm >15nm |

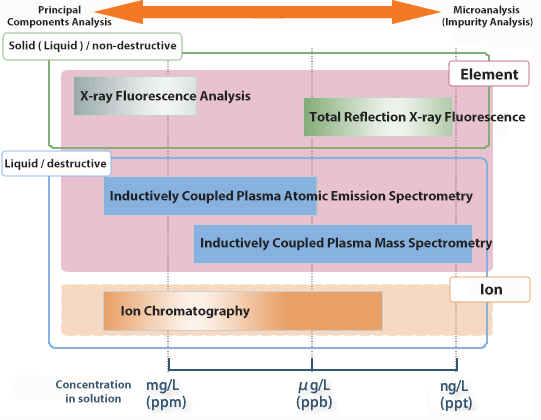

chemical analysis

Main holding equipment

Search by analysis method

| Analysis method | Information obtained | Application example | analysis element | Detection limit concentration |

|---|---|---|---|---|

|

ICP-MS inductively coupled plasma mass spectrometry |

High sensitivity elemental analysis ・Solution analysis ・Fracture analysis |

Analysis of trace metals on Si wafers, trace metals in the environment, and impurities in pure water | Elements other than halogen, inert gas, H, C, N, O | ppt~ (depending on measurement target) |

|

I C Ion chromatographic analysis |

Analysis of highly sensitive solutions Qualitative and quantitative analysis of ions |

Clean room atmosphere survey | anions, cations, organic acid ions | ppt to ppm (depending on measurement target) |

|

TXRF Total reflection X-ray fluorescence analysis |

High sensitivity elemental analysis ・Non-destructive ・Non-contact |

Wafer surface contamination Compound semiconductors other than Si substrates (sapphire, SiC, GaN, etc.) |

Na to U | 109 atoms/ cm2 |

|

GC-MS gas chromatograph mass spectrometry |

Qualitative and quantitative analysis of organic compounds, Structural analysis |

Identification of organic compounds, structure determination, organic matter analysis during CR | Elements other than halogen, inert gas, H, C, N, O | ppb~ (depending on measurement target) |

|

XRF X-ray fluorescence analysis |

Elemental analysis | Thin film/powder/bulk composition qualitative analysis | B~U | ~0.01% |

|

ICP-AES ICP emission spectrometry |

trace elemental analysis, Multi-element analysis |

Composition analysis of various materials and thin films | Elements other than halogen, inert gas, H, C, N, O | ppb~ (depending on measurement target) |

Test characterization

We evaluate and measure the optical properties of optical communication materials, gas permeability, viscoelasticity, thermophysical properties, and powder properties of materials.

Search by analysis content

| Analysis content | Information obtained |

|---|---|

| gas permeability | (Gas/water vapor) permeability |

| Viscoelasticity | Dynamic viscoelasticity (tension, bending, torsion), melt viscoelasticity |

| thermophysical properties | Glass transition point of material, heat value/weight change |

| Powder properties | Specific surface area (BET method), particle size distribution (laser diffraction method/dynamic light scattering method), pore distribution |

| Endotoxin analysis (displays an external site in a new window) | endotoxin concentration |

Analysis flow

At NTT-AT 's Materials Analysis Center, we not only provide analytical data, but also propose problem-solving methods using optimal methods based on the problems raised by our customers.

Step 1 Inquiry(problem submission)

If you have any problems with material evaluation, please feel free to contact us! Please feel free to contact us via the inquiry form or by phone. Please tell us the sample name, sample shape, composition, etc. to the extent possible.

Step 2 Submit your idea

We will propose the optimal analysis method based on the customer's problem, sample, etc. We will conclude a confidentiality agreement upon request.

Step 3 Examining ideas

Our customers' requests (needs) for material evaluation extend beyond simple material analysis to include everything from new material development to process reliability evaluation.

Step 4 Estimate & Plan(Proposal)

We will provide you with an estimate of delivery date, fees, schedule for analysis, etc. If a trial is required, we may conduct a trial analysis in advance.

Step 5 contract

If you have any questions about the quotation, please feel free to contact our sales representative. After placing your order, we will conduct an analysis.

Step 6 Result report

After conducting the analysis, we will deliver the analysis results report along with the delivery note and receipt. Upon request, we will notify you of the results by email prior to delivery.

Step 7 Payment

Please stamp the receipt attached at the time of delivery and return it. We will charge you an analysis fee. As a general rule, payment will be made by bank transfer at the end of the month of the following month.

Please contact us first.

Our analysis services help customers solve various problems.

Please contact us using the contact button on the bottom right.

*If your request is from overseas, we may not be able to respond to your request due to transportation or technology export issues.

Location information

Inside the NTT Atsugi R&D Center (Click here for a map)Location 3-1 Morinosato Wakamiya, Atsugi City, Kanagawa Prefecture 243-0124

Nearest station Hon-Atsugi Station / Aiko-Ishida Station (Odakyu Line)

Click here for information on other locations (headquarters, etc.)

Main public qualification

- Measurement certification office: Vibration acceleration level

- Registered as a designated organization for working environment measurement

Click here for other certifications and official qualifications

close up

close up