Humidity Control Sheet has been introduced in a wide range of fields such as social infrastructure, government offices, local governments, and manufacturers.

Due to its excellent humidity control ability, it has been widely adopted for its effectiveness in reducing equipment failures and maintenance costs. At the time of introduction, it is possible to realize more effective installation by first conducting an evaluation test.

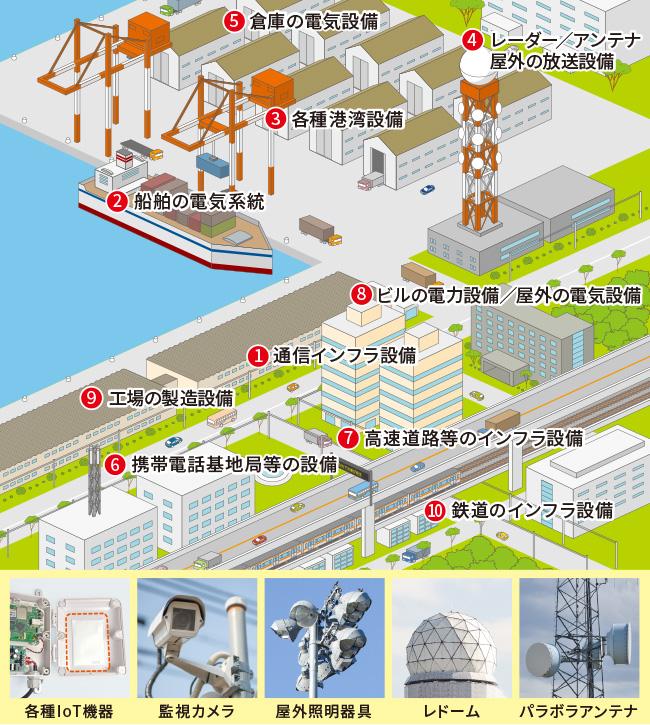

Main case studies

- Introduced as a countermeasure against failures due to condensation that occurs in electrical equipment and equipment, and as a countermeasure against poor contact of terminals.

- Introduced to prevent lowering of insulation resistance due to high humidity and condensation

- Introduced to prevent short circuits in electrical equipment and substrates due to condensation

(1) Communication infrastructure equipment

Connection terminal, MDF, safety device, control panel, wireless device, outdoor Wi-Fi device, antenna, disaster prevention administrative radio, remote monitoring system control panel

(2) Ship electrical system

Control boards, switchboards, connection terminals, antennas, wireless devices, LED lighting

③Various harbor facilities

Control panels for heavy machinery, switchboards, antennas, connection terminals, speakers, LED lighting, disaster prevention cameras

④ Radar/Antenna Outdoor broadcasting equipment

Antennas, weather cameras, speakers, satellite broadcasting equipment, control boards, switchboards, safety devices, disaster prevention speakers

⑤ Warehouse electrical equipment

Switchboards, connection terminals, surveillance cameras, video equipment

⑥ Facilities such as mobile phone base stations

Antennas, amplifiers, switchboards, control boards, monitoring units

⑦Infrastructure facilities such as expressways

ETC, surveillance cameras, indicators, radios, wireless devices, detectors, switchboards, control boards, chargers, automatic payment machines, traffic lights

⑧Electrical equipment for buildings and condominiums/Outdoor electrical equipment

Switchboards, control panels, LED lighting, measuring instruments, smart meters, surveillance cameras, interphones, parking systems

⑨Factory manufacturing equipment

Manufacturing equipment, food and beverage manufacturing equipment, steel manufacturing equipment, printers, robots, pumps

(10) Railway infrastructure

Communications equipment, circuit breakers, traffic lights, broadcasting equipment, surveillance cameras, video equipment, speakers, LED lighting, railway vehicles

Others: Various electric power equipment / solar power generation / wind power generation / outdoor installation sensors / IoT devices / home door intercoms / optical devices / storage of cameras and lenses / musical instruments / etc.

Examples of Humidity Control Sheet 's use in logistics services

| Use scene | Humidity control during product transportation and storage |

| Application example | Metal parts, optical products, electrical products |

Usage scene of Humidity Control Sheet

- For prevention of insulation failure due to condensation in electrical equipment

- As a countermeasure against condensation in places where air conditioners that require power cannot be installed

- For dew condensation countermeasures in factories where temperature and humidity fluctuate greatly

- For dew condensation and mold measures such as storage cabinets and storerooms installed outdoors

- For dew condensation countermeasures in places where equipment and facilities cannot be easily maintained

- For prolonging the life of equipment

- For storage of musical instruments, etc., which are easily affected by moisture

Download materials

| Condensation prevention sheet "Humidity Control Sheet" pamphlet | 1.3 MB | download |

|---|

Material "Why does dew condensation occur in a box with a waterproof structure? 』

Condensation was the cause of equipment failures, malfunctions, and electrical leaks! ?

This document explains why condensation occurs inside waterproof or sealed switchboards and electrical products, and what to do about it. (Japanese)

inquiry

Customers who installed G-Breath had problems like this before installing it.

- Why does condensation occur in a waterproof structure?

- What is the test method to reproduce condensation?

- Even with the waterproof structure and vent filter, condensation occurred. Why?

- I thought the waterproof structure + silica gel would be perfect, but there was condensation!

- A waterproof product has malfunctioned. Water had collected inside. why?

-

Heaters and dehumidifiers were used to prevent condensation, but condensation still occurred.

Although silica gel was added as an additional measure, it requires a lot of equipment and requires labor and cost to replace the silica gel.

If you have similar issues, please contact us!

Our technical staff with experience in troubleshooting infrastructure equipment will contact you.

| See the Humidity Control Sheet product page | ask the person in charge |

close up

close up