Nanoimprint technology is being applied to a wide range of fields at an accelerating pace. We provide nanoimprint molds that are required at various steps in research, development, application, and commercialization.

We have been providing nanoimprint molds for more than 20 years as an application of semiconductor microfabrication technology. During this time, we have received guidance from many customers and have a wealth of experience in providing over 1000 molds.

We receive orders from universities, research institutes, companies, and customers in a wide range of fields such as semiconductors, optics, IT, bio, and medical.

Nanoimprint mold microfabrication technology and manufacturing know-how

■ Mold material

You can specify the material, such as quartz or silicon, that suits your nanoimprint needs.

■ Extremely fine

From minimum 20nm pattern to μm order. High aspect ratios are also possible.

■ Pattern

We can handle everything from repeated arrays of single patterns to complex patterns such as circuit patterns.

■ Multi-step pattern

We also offer multi-level stepped patterns for holograms, etc.

■ Three-dimensional shape

We process a variety of shapes, including microlens arrays (MLA) and inverted pyramid patterns.

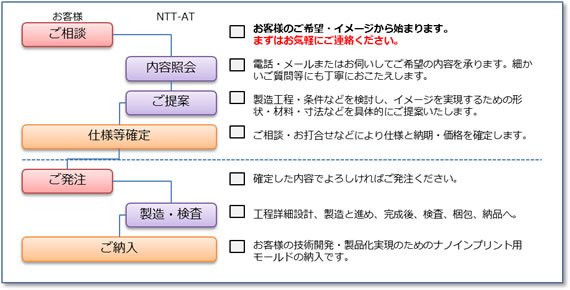

Flow of nanoimprint mold production request

Please feel free to contact us

Prior consultation is very important for custom molds. First of all, please contact us with your wishes and images. We will carefully respond to detailed consultations and questions.

close up

close up