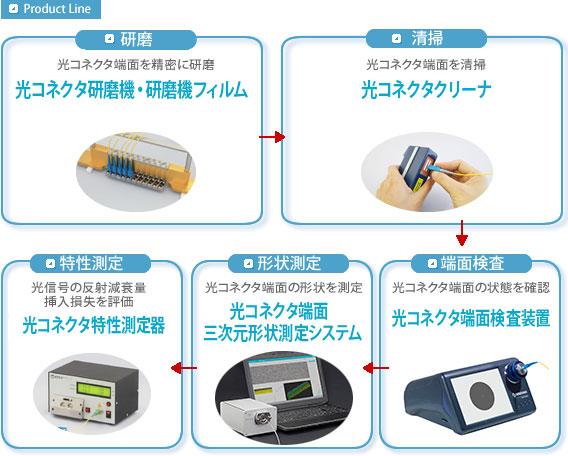

Solutions for speedy, low-cost mass production of high-quality optical connectors

|

|

Precisely polish the end face of the optical connector | |||

|

|

|

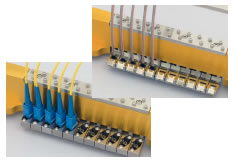

Mass production connector polishing machine

ATP-3200 is an automatic polishing machine that can grind 16 to 24 optical connectors at the same time. The unique polishing trajectory program reduces the waste of polishing paper while shortening the polishing time. |

||

| Precision polishing of the end face of the optical connector plug with optical fiber bonded is required to ensure stable propagation performance and long-term reliability. | ||||

|

|

||||

| Optical connector grinding machine / grinding machine film | ||||

| ・ Handy type optical connector grinding machine POP-311 ・ General-purpose portable optical connector sharpening machine SCP-241 ・ Mass production type optical connector polishing machine ATP-3200 |

||||

|

|

Clean the end face of the optical connector | |||

|

|

Optical connector cleaner

The ultra-fine fiber cloth used in the NEOCLEAN series uses a special material that has been washed in a clean room, making it possible to easily remove even invisible microscopic dirt. |

||

| To ensure that the power of the optical signal is transmitted, it is necessary to remove impurities such as polishing debris. Therefore, cleaning with a dedicated cleaner is essential. | ||||

|

|

||||

| Optical connector cleaner | ||||

| ・ OPTI POP series ・ CLETOP series |

||||

|

|

Check the condition of the end face of the optical connector | |||

|

|

Optical connector end face inspection device

The optical connector end face inspection device enables detailed inspection of the end face by simply inserting the optical connector into the device. For models with a judgment function, a pass / fail judgment can be easily made with the automatic judgment program. |

||

| After cleaning the end face of the optical connector, use an end face inspection device to check for any dirt. If there is dirt or impurities, clean it again. | ||||

|

|

||||

| Optical connector end face end inspection machine series | ||||

|

|

Measure the shape of the end face of the optical connector | |||

|

|

Optical connector end face 3D shape measurement system

This is a non-contact interference type microscope that three-dimensionally measures and evaluates the shape of the end face of an optical connector. |

||

| The end face where the optical connector and the plug come into contact must be hemispherical so that the core centers are in close contact with each other, so the end face shape must be measured accurately. | ||||

|

|

||||

| Optical connector end face 3D shape measurement system | ||||

| ・ MAX + / WIZ + series | ||||

|

|

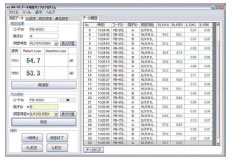

Evaluate the amount of reflection attenuation and insertion loss of optical signals | |||

|

|

Optical connector characteristic measuring instrument

The optical connector characteristic measuring instrument AR-10 can quickly measure the characteristics of two wavelengths (1310nm/1550nm). You can select a hand switch or an attached foot switch to suit your manufacturing site. |

||

| In order to confirm whether the completed optical connector meets the standard performance of the standard, the connector is actually irradiated with light to measure the amount of reflection attenuation and insertion loss, and evaluated and judged. | ||||

|

|

||||

| ※End of sale (Notice of discontinuation of sales of optical connector characteristic measuring instrument AR-10) |

||||

Optical connection construction products

Introducing tools for laying and maintaining optical fiber cables.

close up

close up