| solution point |

|

1Reliable measures introduced to prevent breakdowns caused by humidity and condensation at NTT infrastructure facilities nationwide 2 The introduction cost is higher than silica gel, but it becomes cheaper after using for more than one year. 3 Thin, light, and bendable, so it can be installed in gaps in existing equipment |

Solution

|

Decrease the failure rate of NTT infrastructure equipment and |

Mr. S, who participated in an exchange meeting for mega solar business people, exchanged information about dew condensation measures with the participants. Then I learned that there was a similar problem with NTT equipment and that there was a countermeasure product that solved these problems. Common dehumidifiers such as silica gel lose their performance as they absorb moisture. On the other hand, countermeasure products have excellent moisture absorption and release functions, absorbing moisture when the humidity rises and returning it to the air when the humidity drops. Therefore, the moisture absorption function is restored and the effect can be maintained for a long time. Mr. S became interested and decided to contact NTT Advanced Technology, which handles countermeasures.

While listening to an explanation from the person in charge, I also learned that NTT equipment has a track record of being used without replacement for 10 years. In addition, we are receiving more inquiries from infrastructure companies and equipment manufacturers other than NTT, and we are seeing an increase in the number of installations for our anti-condensation sheet "Humidity Control Sheet," which has been improved so that it can be used with equipment other than NTT. Knew.

|

The cost is also cheaper than silica gel in one year from the start of use |

Regarding the cost, although the introduction cost is more expensive than silica gel, it is a trial calculation that it will be reversed after one year of use because it does not need to be replaced every three months. Mr. S, who had great expectations for Humidity Control Sheet, first introduced it to a part of his equipment to verify its effectiveness. After confirming that the expected results were obtained, we decided to introduce it on a full-scale basis.

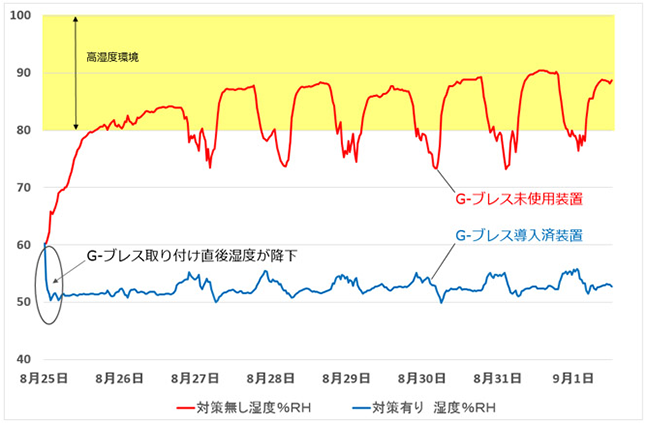

- We introduced Humidity Control Sheet into only one of the devices of the same type. You can see that the humidity inside the device without using Humidity Control Sheet changes drastically between day and night.

- The yellow area at the top of the graph indicates a high humidity environment with a humidity of 80% or higher. In such a high humidity environment, the risk of electronic component failure due to condensation increases.

- On the other hand, the humidity inside the device where the Humidity Control Sheet is installed maintains the humidity within a certain range. This is because the Humidity Control Sheet absorbs and desorbs the rising and falling humidity.

"The Humidity Control Sheet is the very product that I thought, 'I wish I had something like this...'. We were able to prevent condensation while reducing the time and cost of replacing it. We plan to incorporate it into our future designs and proposals. (Mr. S)

| ask the person in charge | See the Humidity Control Sheet product page |

close up

close up