Feature

Ideal for final polishing of optical connector end facesThe optical connector end face can be polished without scratches or dirt. In addition, the binder of the polishing film and silica abrasive grains do not adhere to the object to be polished. The polish level achieves ultra-low return loss (UPC).

Simultaneous realization of long life, which ADS excels atA final polishing film that maintains the final finishing performance and simultaneously achieves a long life with stable polishing power. High performance polishing can also be achieved with distilled water.

Significantly improved fiber dent phenomenonIn particular, we have greatly improved the fiber dent that occurs when polishing a φ1.25mm ferrule multiple times. Prevents sudden deterioration of fiber dents even after repeated use.

specification

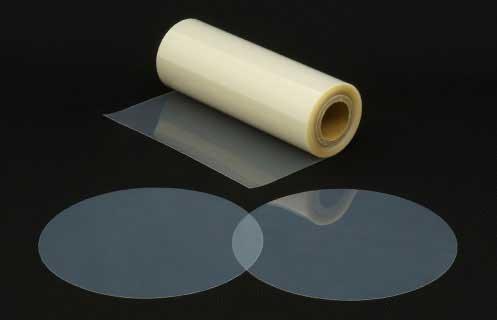

| standard size | Disk type: 127mm (5inch) dia. (100 sheets/set) Roll type: 140mm (5.5inch) x 12m (1/set) |

|---|---|

| film color | ADS: Colorless and transparent (Round type has "ADS" stamped on the tab) ADS-NEXT: White translucent (Round type has "NEXT" stamped on the tab) ADS-NEO: White translucent (Round type has "NEO" stamped on the tab) |

| base thickness | 75 µm (3 mils) |

| Applicable ferrule | 2.5mm diameter zirconia ferrule 1.25mm diameter zirconia ferrule |

| Storage conditions | Temperature: 10-30 degrees Celsius, humidity 30-60%, non-condensing |

lineup

ADS

Over 500 user companies! final polishing film boasting the world's top-level market share

Can be used for a wide range of polishing machines, construction methods, and connectors.

| Return loss value | -52 to -56dB (PC), -80dB or more (APC) |

|---|---|

| polishing water | EtOH20% water is recommended (purified water can also be used) |

| Applicable polishing machine | ATP-3200, center pressure type, square jig type |

ADS-NEXT

final polishing film that prevents fiber dents

Prevents rapid deterioration of fiber dents even after repeated use of the film. Especially suitable for ATP-3200.

| Return loss value | -57 to -60dB (PC), -80dB or more (APC) |

|---|---|

| polishing water | purified water |

| Applicable polishing machine | ATP-3200, central pressure type |

NEW ADS-NEO

final polishing film that greatly prevents fiber dents caused by high-pressure polishing

A new-generation final polishing film optimized for high-pressure polishing.

| Return loss value | -56 to -59dB (PC), -80dB or more (APC) |

|---|---|

| polishing water | purified water |

| Applicable polishing machine | ATP-3200, square jig type |

Polishing conditions (LC/UPC)

Grinding machine: center pressurized grinding machine

| Process name | Used film | time (seconds) | |

|---|---|---|---|

| 1 | adhesive removal | AAS-WA09A-R140-12 | 30 |

| 2 | Primary polishing | AAS-DM09-127 | 30 |

| 3 | secondary polishing | AAS-DM01-127 | 60 |

| 4 | final polishing | ADS-NEXT-127 | 30 |

Polishing machine: Square jig type polishing machine

| Process name | Used film | time (seconds) | |

|---|---|---|---|

| 1 | adhesive removal | AAS-WA09A-R140-12 | 30 |

| 2 | Primary polishing | AAS-DM09-127 | 25 |

| 3 | secondary polishing | AAS-DM01-127 | 35 |

| 4 | final polishing | ADS-NEO-127 | 25 |

Polishing machine: ATP-3200 polishing machine (independent pressure type)

| Process name | Used film | time (seconds) | |

|---|---|---|---|

| 1 | adhesive removal | AAS-WA09A-R140-12 | 15+30 |

| 2 | Primary polishing | AAS-DM01-R140-12 | 90 |

| 4 | final polishing | ADS-NEXT-R140 | 60 |

*Design and specifications are subject to change without notice.

Download materials

Product Safety Data Sheet (SDS) for Optical Connector Polishing Film and Polishing Fluid

List of Material Safety Data Sheets

close up

close up