For customers considering introduction of optical connector end face inspection equipment

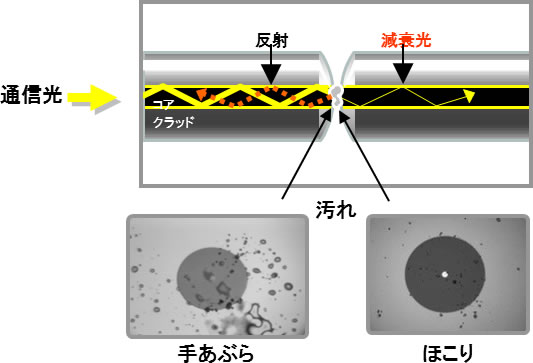

Contamination on the end face of optical connectors accounts for a large proportion of the causes of defects in optical networks.

Contamination on optical connector endfaces that cannot be seen with the naked eye causes increased reflection and loss.

|

|

Advantages of observing the optical connector end face before connecting the optical connector

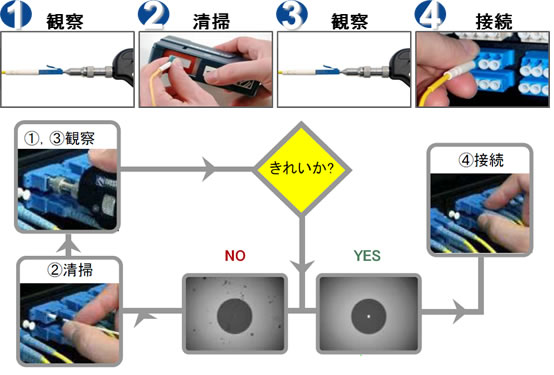

Observing the end face before connecting can prevent failures due to contamination on the end face.

Scratches and stains on the end face can be visually identified, enabling the identification of the location of loss occurrence and shortening of network downtime.

We recommend the following cycle to maintain a healthy network.

Checking the state of the optical connector end face is essential for maintaining a sound network!

Please take a look at the detailed information we have prepared.

To all optical connection workers and contractors

Very popular third edition of optical connector-related materials

[Booklet] You can download a PDF of the effects of contamination on the end faces of optical connectors and countermeasures.

Installation example of optical connector end face inspection equipment

Nippon Television Network Corporation

Introduced product: FBP-HD3-PA (*1)

*1: FBP-HD3-PA has been discontinued.

As a substitute, we sell the end face monitor series with an automatic judgment function.

NTT-ME Co., Ltd.

Introduced product: FBP-NS-P01 (*2)

*2: FBP-NS-P01 has been discontinued.

We are currently selling the successor FBP-NS-P101.

close up

close up