- Less internal stress during curing and heat cycle

- Low moisture permeability even at high temperatures

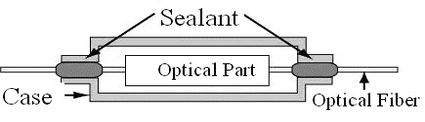

Example of use

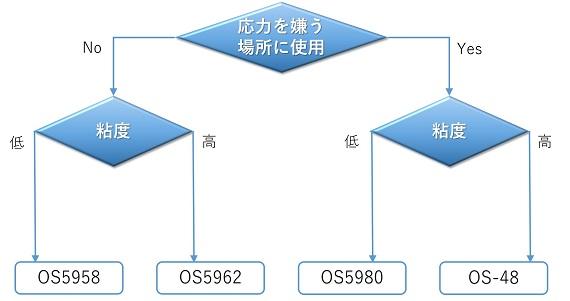

What type of adhesive are you looking for?

Please use it for selection of adhesive.

Specification

| model number [Main component] |

Curing conditions |

Appearance (color) |

Mixing ratio *1 |

pot Life (min) |

moisture permeability coefficient * 2 |

Hardness *3 |

adhesion |

Feature |

|---|---|---|---|---|---|---|---|---|

| OS5958 [A: Epoxy resin] [B: Amine curing agent] |

room temperature 24 hours or 80°C 1 hour |

A: White paste B: Yellow transparent liquid |

10/3 | 120 | 1.6×10-8 | 47 | 131 | high moisture resistance, Pot life length |

| OS5962 [A: Epoxy resin] [B: Amine curing agent] |

A: White paste B: Yellow transparent liquid |

21/3 | 120 | 0.7×10-8 | 66 | 146 | high moisture resistance, high viscosity, Pot life length |

|

| OS5980 [A: amine] [B: modified epoxy] |

80°C for 1 hour | A: Transparent paste B: Black paste |

1/2 | 120 | 3×10-7 | 20 | 24 | high flexibility |

|

polybutylene resin] |

or 100℃ 1 hour |

B: Black paste |

|

|

(75℃90%) |

|

|

|

*1...weight ratio

*2...Unit of moisture permeability coefficient (cc・cm/cmHg・cm 2 ・s), measurement condition 85℃ 85%RH

*3...Shore D

*4...Shear bond strength against SUS (kgf/cm 2)

*5...Discontinued due to difficulty in procuring raw materials

The characteristic values in the table are sample measurement values, not guaranteed values.

close up

close up