End of sales of adhesive for fiber array assembly

Sales of AT3727E and AT3728E will end when stocks run out.

(→Sales have ended)

AT9390, AT9968, and AT3925Mwill continue to be sold.

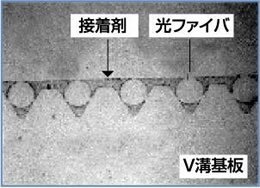

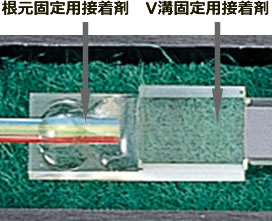

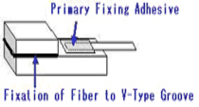

A fiber array used for multicore input/output of optical waveguide devices.

V-groove fixing adhesive is required for assembly.

Among them, the E series, which is particularly durable, has been well received by many customers.

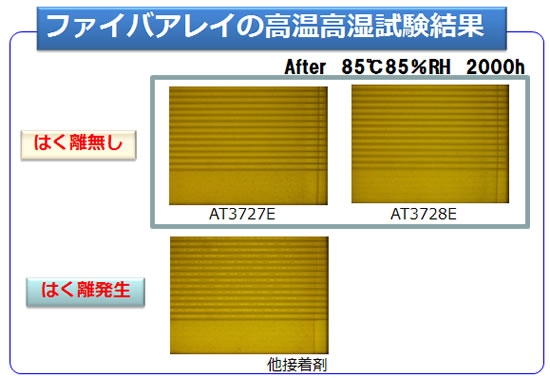

Excellent durability that enables highly reliable fiber arrays

The fiber V-groove fixing adhesive E series is low-priced, but has achieved durability that exceeds that of the conventional product AT9390, which excels in high humidity resistance.

Two types of lineup that can be selected according to the application

Two types with different glass transition temperatures are available, so please select one according to the usage environment.

Easy workability by UV curing

Due to UV curing, the time to adhesion is short, leading to shortening of work time.

Characteristics of Adhesives for Array Assembly

-

excellent durability

-

Easy-to-work viscosity

For fiber V-groove fixing: low viscosity

Model number: AT9390, AT9968, AT3925M

For fiber root fixation: non-fluid

Model number: AT9575M, AT8105

-

Simple workability by UV curing

Example of use

Specification

|

model number [Main component] |

Apply part |

Curing conditions [Irradiation intensity, time] |

viscosity (mPa・s) |

glass metastasis temperature Tg (°C) |

hardness Shore D |

Adhesion strength (kgf/ cm2) |

Features |

|---|---|---|---|---|---|---|---|

|

AT3925M [Epoxy] (*1) |

A |

100mW/ cm2 10 minutes |

200 | 219 | 88 | >99 |

high elasticity, High heat resistance |

|

AT9390 [Epoxy] (*1) |

A |

30mW/ cm2 10 minutes |

600 | 131 | 81 | >194 | High moisture resistance |

|

AT9968 [Epoxy] (*1) |

A |

100mW/ cm2 10 minutes |

70 | 181 | 85 | >143 | low viscosity |

|

AT9575M [Epoxy] |

B |

100mW/ cm2 10 minutes |

paste | 42 | 35 | >221 |

high durability, |

|

AT8105 [Acrylate] |

B |

10mW/ cm2 5 minutes |

paste | 103 | 78 | >226 |

high durability, illiquidity, High Tg |

*1...This is a product containing "Non-medicinal deleterious substances" (Please refer to SDS (MSDS) for handling)

The characteristic values in the table are sample measurement values, not guaranteed values.

close up

close up