Because it is an ultraviolet curable resin, it is possible to fabricate waveguides by various methods.

- direct exposure method

- RIE method

- Stamper method

Feature

- 屈折率を0.001単位で指定可能

- excellent light transmission

- Viscosity can be adjusted, and film thickness controllability during spin coating is good.

- Refractive index can be controlled in the range of 1.43 to 1.62 with an accuracy of ±0.005

[Example of application] Cladding of optical waveguide

It has excellent flatness and refractive index matching, and is also available in a solder heat resistant grade, so it can also be applied to interlayer insulating films.

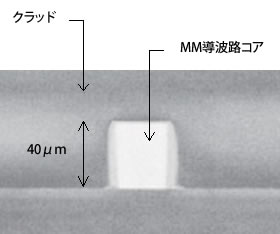

Example of waveguide fabrication by direct exposure method

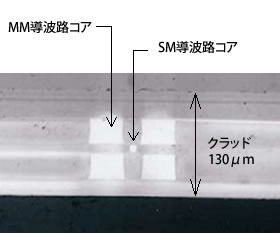

Fabrication example of multistage waveguide

(Epoxy resin is used for clad/MM waveguide core)

(Epoxy resin is used for clad/MM waveguide core)

Due to its excellent flatness, it is also suitable for creating multistage waveguides.

Specification

Core/cladding material set (*1)

| Principal component | Refractive index @ 830nm | Feature |

|---|---|---|

| epoxy |

Core: 1.53±0.005

Cladding: 1.51±0.005 |

Core: Viscosity=2,200mPas Tg=222℃ Δn=1.3% (@830nm) Clad: Viscosity=2,900mPas Tg=200℃ |

Refractive index adjustment type

| Principal component | Refractive index adjustment range | Feature |

|---|---|---|

| epoxy | nD=1.43~1.62 |

Adjustable viscosity (It is easy to control the film thickness of spin coating.) |

close up

close up