FAQ about Optical Adhesives

We introduce frequently asked questions about optical adhesives as FAQs.

This FAQ may not apply to resins other than adhesives and sealing materials. If you have any questions about resins other than adhesives and sealing materials, please contact us using the inquiry form.

| Q1 | Where can I buy it? I would like an estimate. |

|---|---|

| A1 | Please contact us from the inquiry form. |

| Q2 | How can I obtain the SDS (MSDS) and instruction manual? |

|---|---|

| A2 | Please contact us from the inquiry form. |

| Q3 | I would like a sample. |

|---|---|

| A3 | We do not provide free samples. It is sold in units of 5 g or 10 g as a paid sample. |

| Q4 | I want to know how the product will be packed when it is delivered. |

|---|---|

| A4 | A default container is a brown glass bottle. |

| Q5 | Is it possible to deliver in a syringe? Is it possible to put it in the syringe provided by our company? |

|---|---|

| A5 | We do not recommend shipping syringes due to the potential for adhesive leakage during shipping. If you wish, we can deliver our standard syringes 3ml, 5ml, 10ml (manufactured by Musashi Engineering, model number PSY-EU without memory). It is also possible to deliver it in the supplied syringe. We are not responsible for any leakage during transportation. |

| Q6 | Is the adhesive defoamed? |

|---|---|

| A6 | It is defoamed before sealing. There is no problem to use it as it is. If you want to defoam yourself, we recommend using a centrifugal deaerator or a vacuum deaerator. |

| Q7 | Do I need to treat the adhesive surface before using the adhesive? |

|---|---|

| A7 | Make sure that the adhesive surface is free of dust, oil, etc. When wiping with an organic solvent, dew condensation may occur due to a drop in temperature due to volatilization of the organic solvent, so dry thoroughly with an air gun, etc. Depending on the material, bonding strength can be improved by treatment with a coupling agent, ozone, or plasma. |

| Q8 | Is the adhesive you sell UV curable or heat curable? |

|---|---|

| A8 | Catalog products are UV curable adhesives. However, heat treatment after hardening can be expected to alleviate the internal stress generated during hardening, promoting long-term reliability. Please refer to Q14 for the difference between epoxy and acrylate in curing mechanism. |

| Q9 | What are the standard curing conditions described in the instruction manual? Is it possible to cure under conditions other than those described in the instruction manual? |

|---|---|

| A9 | Standard curing conditions are set with the minimum illumination and time required for curing. It is assumed that the internal stress that occurs during curing will be minimized by setting the minimum illumination. If you want to shorten the curing time, please refer to Q11. |

| Q10 | What kind of UV equipment should be used to cure UV curable adhesives? |

|---|---|

| A10 | Please use a UV irradiator that uses a high-pressure mercury lamp, metal halide lamp, etc. that can emit light with a wavelength of 365 nm. It is possible to use an LED with a peak at 365nm, but since the LED is a single wavelength, the total energy content is lower than a lamp with a broad output wavelength. Therefore, when using LEDs, it is necessary to adjust the irradiation time or irradiation intensity in order to make the total amount of energy the same (approximately three times that of high-pressure mercury lamps and metal hydro lamps). |

| Q11 | Can I shorten the curing time? |

|---|---|

| A11 | We recommend slow curing to reduce distortion and stress, but you can shorten the curing time by increasing the UV irradiation intensity if necessary. The adhesive will cure if it receives the amount of energy required for curing. For example, doubling the intensity of the UV light will halve the curing time. However, rapid curing in a short time tends to create strain and internal stresses that can cause cracking and delamination. If you need to shorten the curing time, start with the recommended irradiation intensity and gradually increase the irradiation intensity for step cure, or first cure the adhesive surface with high irradiation intensity (temporary fixing) and then slowly apply the entire surface. Let it harden. Please refer to Q16 for how to use Step Cure. |

| Q12 | Is heat treatment necessary after UV irradiation? What is the recommended heat treatment method? |

|---|---|

| A12 |

Heat treatment is recommended for improving reliability. Heat treatment is not required when using only to check adhesion.

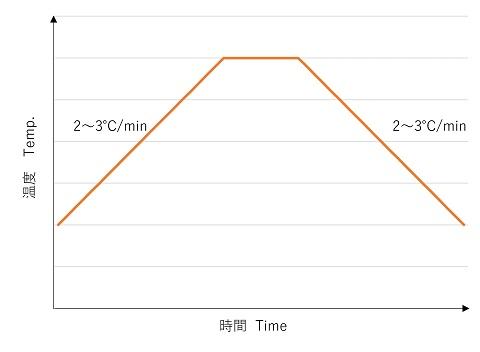

During curing, internal stress is generated, which causes a decrease in adhesive strength (exfoliation) during reliability testing. Heat treatment above Tg is required to alleviate the occurrence of internal stress, but the heat treatment conditions are described in the instruction manual in consideration of cases where heating above Tg is difficult. If you need an instruction manual, please contact us using the inquiry form. Raise the temperature slowly during heat treatment to avoid rapid heating, and lower the temperature slowly after heat treatment to avoid rapid cooling. A change of 2-3°C per minute is ideal.

Please refer to the figure below (example of temperature rise and fall pattern). If you want to shorten the heat treatment time, you can increase the heating rate. But don't skip the cooling process. Ideally, it should be slowly lowered and allowed to come to room temperature before removal. If you don't have time to bring it back to room temperature, you can remove it from the heater as soon as it cools down to 40°C.

Please note that if you cool it rapidly, internal stress will occur again.

Temperature rise and fall pattern example |

| Q13 | There are areas that are shaded and UV rays do not reach. What should I do? |

|---|---|

| A13 |

Any shadowed areas will leave uncured adhesive and cause delamination. Consider applying the UV light from different angles so that the UV light reaches all parts of the adhesive, essentially without shadows. However, with epoxy glue, if the shaded area is very small, it will cure to some extent. A post-irradiation heat treatment helps the curing (dark reaction) progress further. (This is not applicable for acrylate adhesives. Please refer to Q14 for details.

|

| Q14 | How do UV curable adhesives cure? |

|---|---|

| A14 |

Epoxies and acrylates have different curing reactions.

Epoxies undergo cationic polymerization. When exposed to UV light, an organic acid is generated from the photopolymerization initiator and the curing reaction of the epoxy resin occurs. Even if the UV irradiation is stopped, the curing reaction continues because the organic acid remains. After UV irradiation, you can proceed with the curing of the uncured part by heat treatment.

On the other hand, acrylates undergo radical polymerization. When UV light is applied, radicals are generated from the photopolymerization initiator, causing a curing reaction of the acrylic resin. When the UV irradiation is stopped, the generation of radicals stops and the curing reaction also stops. Care must be taken in areas where the resin is in contact with oxygen, as the radicals react with oxygen and hinder the curing of the resin. Please refer to Q15 for measures against oxygen inhibition.

|

| Q15 | After curing the acrylate adhesive, it does not set well or is sticky. What is the cause? How can I make it harden properly? |

|---|---|

| A15 | If the surface of the acrylate adhesive is in contact with air during UV light irradiation, the oxygen in the air will inhibit curing, so the part exposed to air will not cure. The inside is hardened, but if you are concerned about stickiness, please wipe the surface with an organic solvent. To avoid such oxygen inhibition effects, we recommend curing in a nitrogen environment. In addition, there is no oxygen inhibition in the curing of epoxy adhesives. |

| Q16 | How do you do a step cure to shorten the curing time? |

|---|---|

| A16 |

Under standard curing conditions and the same total amount of UV light energy, it will cure.

For example, if the standard curing condition is 100mW/cm 2 ×5 minutes, the total energy is

100m/ Wcm2 x 300 seconds = 30,000mJ becomes. <An example of “5-stage step cure” to achieve 30,000 mJ, shortening 5 minutes to 2 minutes>

Step 1: 100mW/ cm2 x 45 seconds (4,500mJ)

Step 2: 250mW/ cm2 x 30 seconds (7,500mJ)

Step 3: 350mW/cm 2 × 20 seconds (7,000mJ)

Step 4: 400mW/cm 2 × 15 seconds (6,000mJ)

Step 3: 500mW/cm 2 × 10 seconds (5,000mJ)

→Total energy 30,000mJ

|

| Q17 | How can I know if the adhesive has cured? How do I measure? |

|---|---|

| A17 |

If the glass does not move after bonding, it is cured. Or, if you dispense adhesive onto the glass and cure it, and then touch it with a needle, it is cured if it does not penetrate to the glass.

If the glass moves or the adhesive becomes gel-like and shifts, it is not yet cured. Please be careful when making your decision as acrylate adhesives are anaerobic and do not harden on the surface.

Hardness measurement and adhesion strength measurement are relatively easy methods to check the cured state.

|

| Q18 | Does the refractive index of the adhesive have wavelength dependence? |

|---|---|

| A18 | There is wavelength dependence. Please check the measurement wavelength when checking the refractive index in the data sheet. Our measurable wavelengths are sodium D line (589nm), 403nm, 633nm, 830nm, 1300nm and 1550nm. Please specify the desired wavelength when ordering a refractive index adjusted product. |

| Q19 | Do you have reliability test data for heat and moisture resistance? |

|---|---|

| A19 | Catalog products have undergone a heat cycle test (121°C/100%, -40 to 80°C). Please contact us. |

| Q20 | High temperature processes like 260C are planned. Will the adhesive hold up? |

|---|---|

| A20 |

It depends on the type of adhesive, usage and design.

|

| Q21 | What is the warranty period and storage conditions? |

|---|---|

| A21 | If the product is stored under the recommended conditions, the warranty period is 3 months, whether the product is opened or not. Storage conditions vary depending on the product. Please refer to the enclosed instruction manual. If you do not have the instruction manual, please contact the place of purchase. |

| Q22 | Is it possible to extend the warranty period for more than 3 months? |

|---|---|

| A22 | We do not extend the warranty period. It is up to the customer to decide whether to use the product after the warranty period has expired. For refrigerated storage, please refer to the storage conditions here (PDF 184 KB). |

| Q23 | Can product shelf life be extended by storing in the refrigerator or freezer? |

|---|---|

| A23 | Even if the product is stored at low temperature, the warranty period is not extended. Adhesive stability can be expected by lowering the storage temperature, but there may be effects such as moisture absorption when returning to room temperature. |

close up

close up